Shop

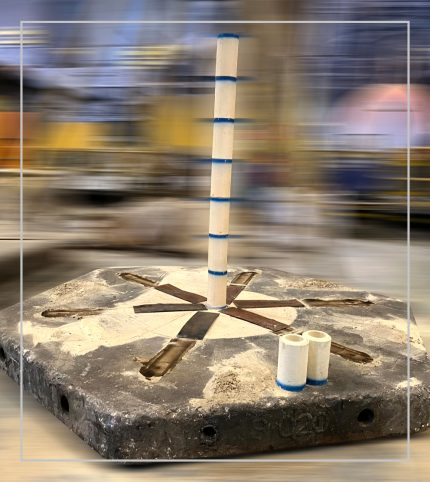

Bottom Pouring Sets for Ingot Teeming – Ceramic Holloware

Complete line of ceramic holloware for indirect casting, according to the casting slab design.

Line in silico-aluminous material and mullite.

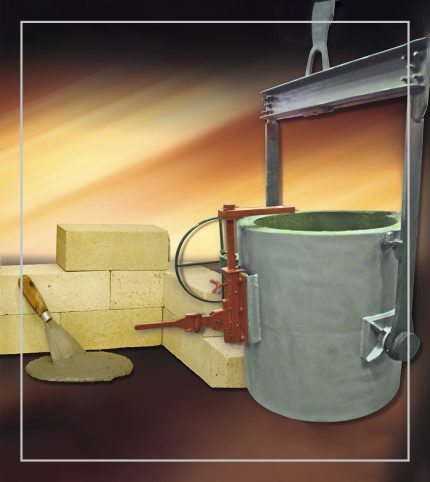

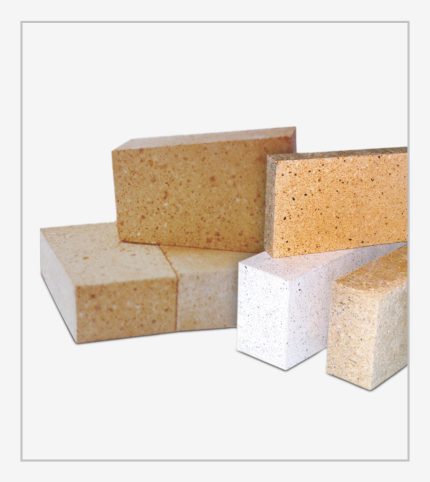

Bricks and Mortars

Aluminous bricks for lining and construction of equipment and mortars for different application conditions, dry and ready for use.

Bricks and Mortars

Bricks for lining and construction of equipment and mortars for different application conditions, dry and ready for use.

Castables and Mortars

Vibrated, free-flowing or projection castables for application in ladles, tundish, floor, and repairs.

Castables, plastics and non-stick paints

Complete line of monolithics specially developed for the aluminum segment and its different usage and application needs.

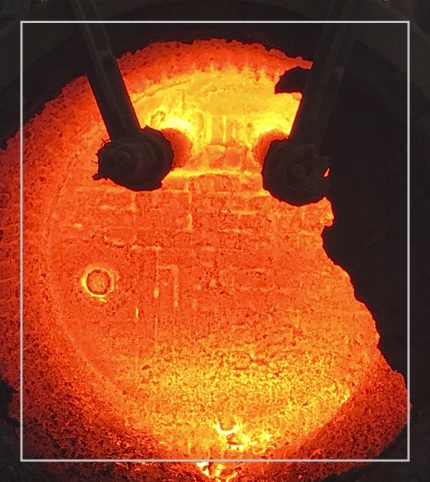

Concrete for construction and renovation of equipment

Chemically admixed and low-cement concrete, which can be applied by vibration or self-draining, suitable for lining all types of furnaces, such as melting towers, reverberates, rotaries, dosifiers, in addition to transport pans and chutes.

With properties to withstand contact with liquid aluminum under different conditions of use, preventing the formation of corundum, adhesion of the metal in addition to having high resistance to abrasion.

Insulating and semi-insulating concrete

Composed of light aggregates of low thermal conductivity, indicated according to the desired temperature for the project, and can be applied by vibration, punching, projection or spooning, also with properties to withstand contact with liquid aluminum.

Monolithic for repairs and protective paints

From conventional concrete for projection, chemically added, ready-to-use plastics, mortars, protective and non-stick paints.

Ceramics and glass

In the ceramics industry, we operate in the maintenance of insulating coatings, manufacture of burner blocks, and also special blocks for red ceramics, such as “fire pass” type blocks and support blocks and linings for kiln carriages.

For the glass industry, we manufacture special, high-resistance pre-molded parts with zirconia and chromium oxide.

Coke oven

We operate in different stages of the process, with materials for inspection blocks, door frames and lintels, shotcrete and repairs, dry sills and others.

Concrete and Plastics

Vibrated castabels, self-flowing or projection castables for application in pouring ladle, runners and gutters for ovens and other equipment.

Plastic masses for conformation or repairs in ovens and pans.

Containers for transporting liquid aluminum

Technology developed especially for these coatings, with low thermal conductivity concrete and high resistance to direct contact with liquid aluminum, projects to maximize transport capacity and reduce energy costs and structural weight.

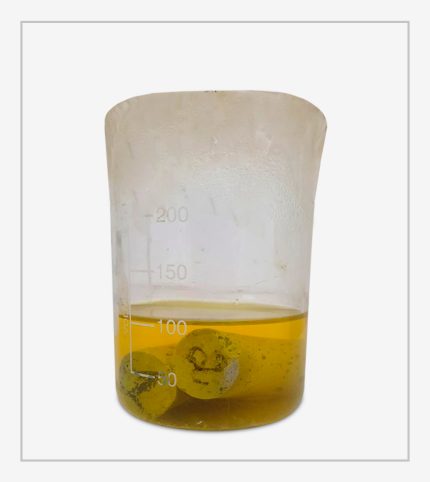

Degassing filter boxes

Non-wettable aluminum, aluminous silica and electrofused silica refractories, with projects focused on reducing thermal loss.

Liquid aluminum transfer gutters

Non-wettable aluminum refractories in aluminous silica material or electrofused silica, resistant to abrasion and thermal shock, in modules that can include a thermal insulation project.

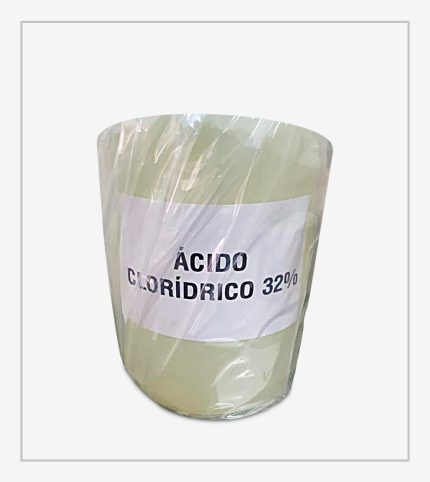

Oil and Gas

Concretes with high resistance to abrasion and chemical attack generated by gases, for application in various equipment and temperature zones for gas treatment chambers, and semi-insulating coatings for exhaust ducts.

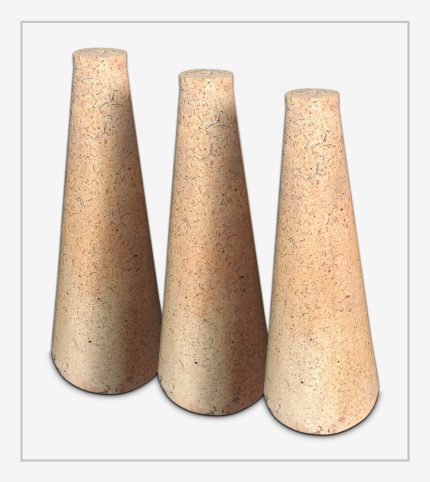

Parts for transfer and feeding

Special parts for low pressure furnaces, such as spouts, feeding cones with high resistance to abrasion and thermal shock.

We also work with special refractories with high mechanical and abrasion resistance for loading areas in melting tower furnaces.

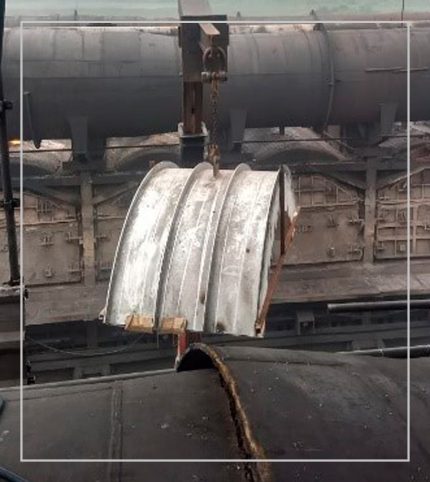

Precast parts

Parts specially sized for each piece of equipment, from spouts for electric arc furnaces, Delta for electric arc furnaces and ladle furnaces, shock plates, shields and pouring basins.

Refractory Kits

Pre-assembled pouring systems according to the customer’s design, offering speed and safety in the molding stage, resulting in significant productivity gains.